Voron Headbed: Unterschied zwischen den Versionen

(Die Seite wurde neu angelegt: „My LDO Voron 2.4 350 Rev D started smelling very bad after approx 200h of printing over the last year. Please don't come with comments like "usual ABS SMELL".…“) |

Admin (Diskussion | Beiträge) Keine Bearbeitungszusammenfassung |

||

| (8 dazwischenliegende Versionen von 2 Benutzern werden nicht angezeigt) | |||

| Zeile 3: | Zeile 3: | ||

This smell is really horrible and spreads arround in the complete house. | This smell is really horrible and spreads arround in the complete house. | ||

The reason seems to be using the heatbed at 120deg for drying silika for a long time-period ( | The reason seems to be using the heatbed at 120deg for drying silika for a long time-period (> 8h). | ||

Now I want to replace the heatplate of the bed. | Now I want to replace the heatplate of the bed, which smells like that bad taste. | ||

Fabreeko offers heatbeds with suitable | Fabreeko offers heatbeds with suitable adhesive, or probably even without. But they are currently out of stock | ||

and I dont know how to order from | and I dont know how to order from Germany (probably quite expensive, when including shipping and taxes) | ||

The idea raised up, to use heatresistors as replacement for the silicon mate. | |||

30 times 100 Ohm resistors (50 W) were skrewed to the aluminum plate into | |||

60 M3 threads drilled into the back of the plate. This should be much more than enough to heat with approx 600 Watt. | |||

The resistors were connected 5 in series 6 times in parallel makes (500/6 Ohm = 83 Ohm). P=U²/R=230^2/83 Watt=640 Watt. | |||

HY510 was used as conductive paste, which seems to be a good compromise between quality and price. | |||

This conductive paste can be used in a temperature range, which is far outside the usual use-cases for a 3D printer. | |||

The 5 series resistors very soldered directly together, the endconnection was done via silconcables and wago-clamps | |||

Before starting the build, I estimated, the temperature fluctuation due to the distance of the load-resistors: [[Voron_TempFluct]] | |||

BOM: | |||

* 50W 100 Ohm resistors 75 Stk. ~45,- Eur | |||

* HY510 ~6,- Eur (30g (>10ml), but only 3ml needed) | |||

* M3x6 75 Stk 7,- Eur | |||

* Silicon cable 2m 5,- Eur | |||

* T-fuse (125° 15 A) reused from Voron 5,- | |||

* 3950 thermistor (reused) 5,- Eur | |||

* M3 thread whirling tool 5,- Eur (Used to CNC mill the M3 threads) | |||

* D2 end milling cutter 5,- Eur | |||

* D4 shaft for my CNC motor 9,- Eur | |||

* wago clamp 2 Stk 5 each 2,- Eur | |||

Sum: 94,- Eur | |||

Uncountable amount of coffee and time excluded from this calculation makes it more cheap, than the Fabreeko silicon heater | |||

TODO show foto of my thermo camera for two different temperatures. | |||

TODO show heating curve + stabilisation with calibrated PID (+/- 0.1 deg for 70 and 100° celsius as initial result) | |||

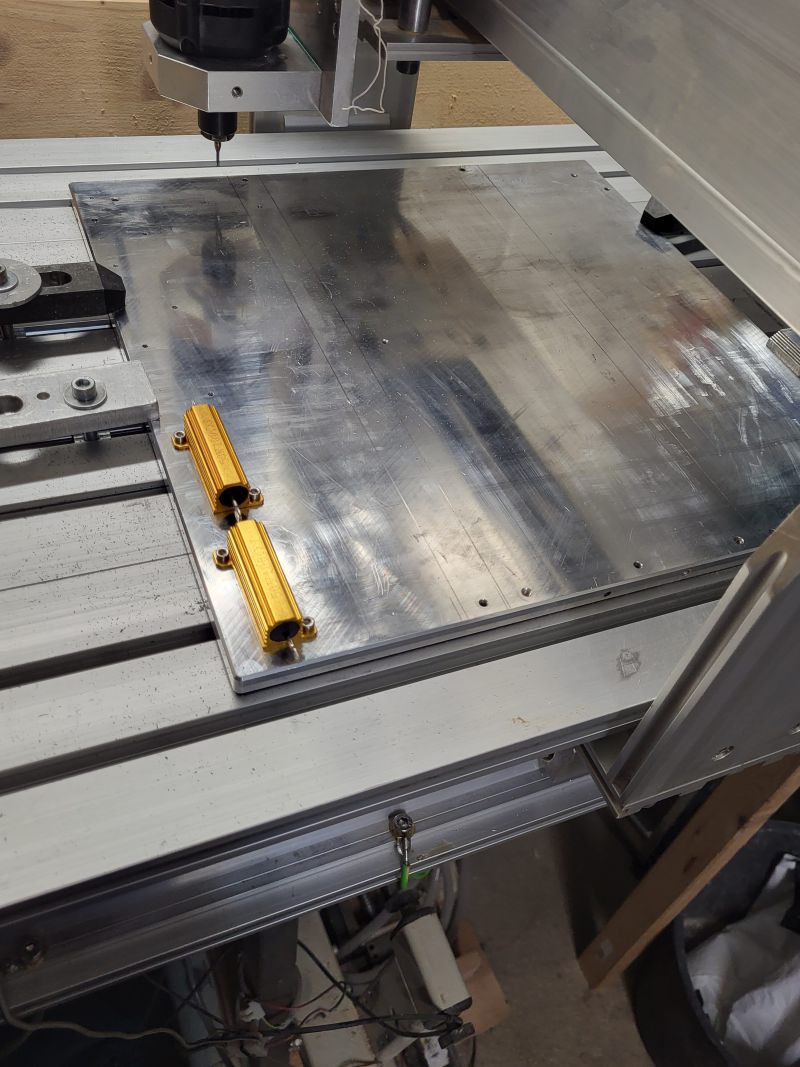

[[File:20251226_120024.jpg|800px|The first two are done]] | |||

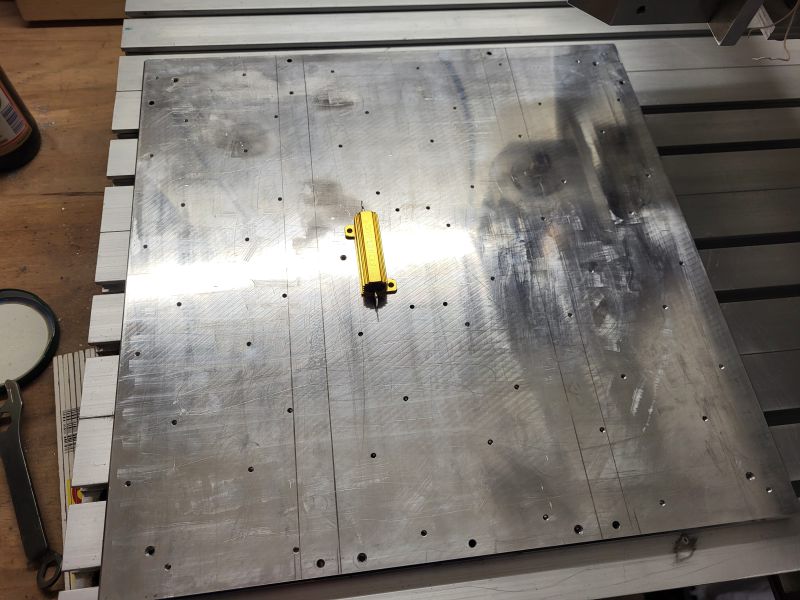

[[File:20251227_130642.jpg|800px|All M3 done]] | |||

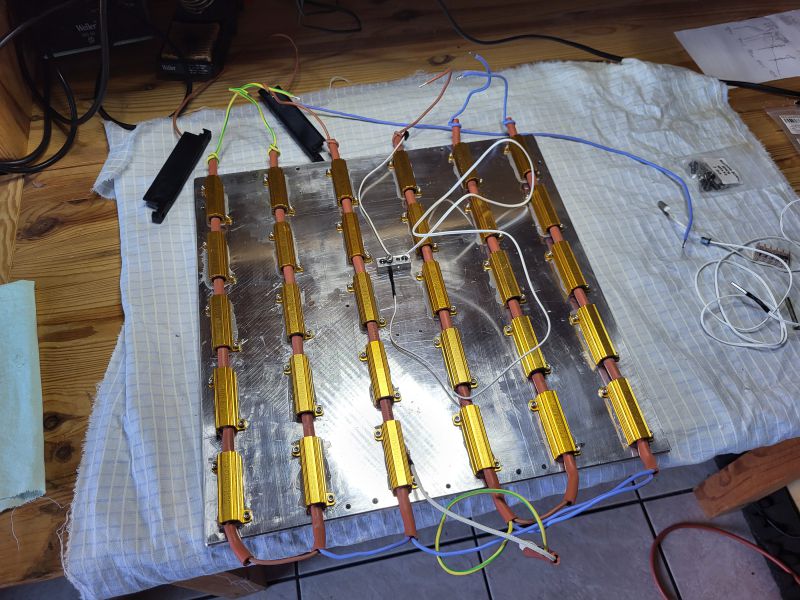

[[File:20251228_114337.jpg|800px|Alltogether]] | |||

The aluminum block in the middle was foreseen to hold a PT1000 and a second 3950 thermistor | |||

but first measurements have shown, that a 3mm hole in the middle of the back of the aluminum plate serves better and faster for the PID. | |||

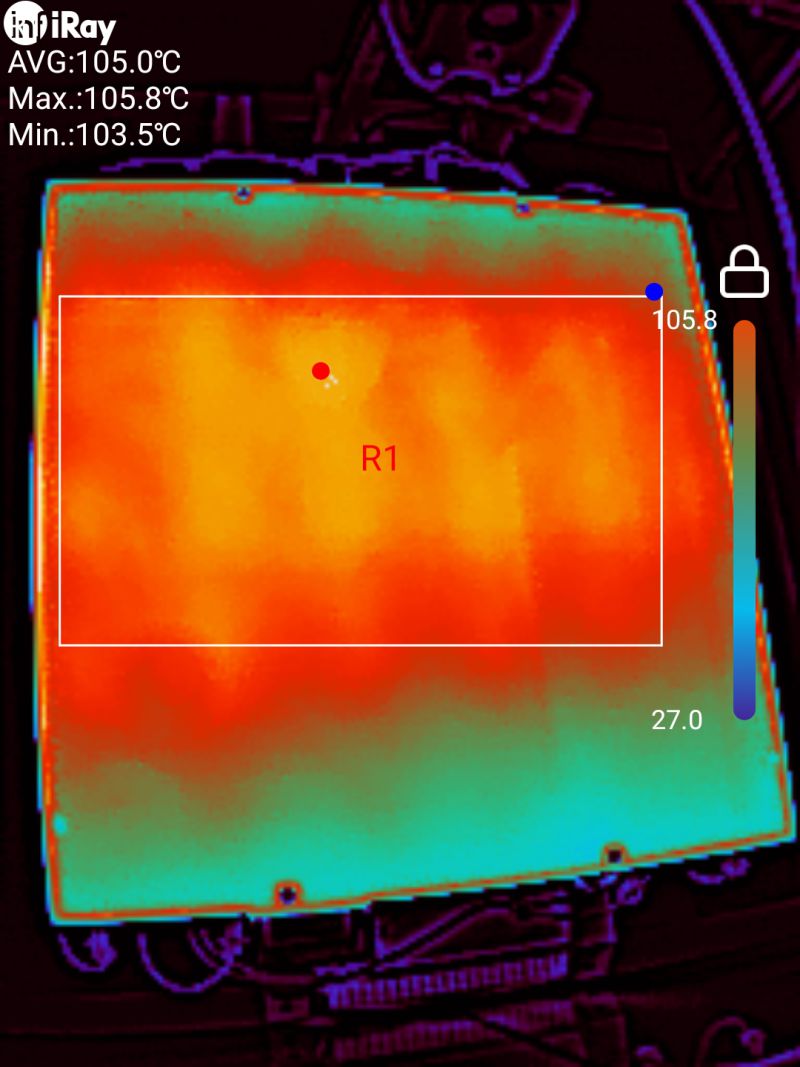

[[File:20251229_175255.jpg|800px|New bedheater in action]] | |||

Temperature measurement with thermo camera shows convincing results: | |||

The temperature in the back and front are too low. This is probably due to the Ventilator of the Nevermore. Unluckily I do not have a photo, when the original LDO heater was equipped. | |||

[[File:Xinf_260121_210333_090_wiki.jpg|800px|temperature using thermocam]] | |||

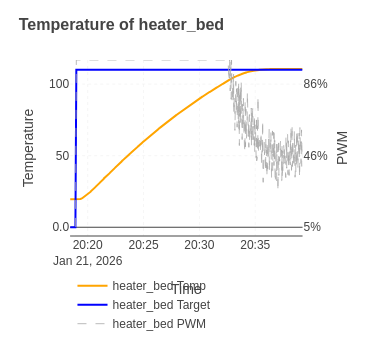

temperature and heater curve, when heating up from room temperature to 110°C (230 F) from klippy.log | |||

[[File:klippy_T110curve.png|800px|temperature measurement]] | |||

Aktuelle Version vom 23. Januar 2026, 15:07 Uhr

My LDO Voron 2.4 350 Rev D started smelling very bad after approx 200h of printing over the last year. Please don't come with comments like "usual ABS SMELL". It is definitely not the ABS! This smell is really horrible and spreads arround in the complete house.

The reason seems to be using the heatbed at 120deg for drying silika for a long time-period (> 8h).

Now I want to replace the heatplate of the bed, which smells like that bad taste.

Fabreeko offers heatbeds with suitable adhesive, or probably even without. But they are currently out of stock and I dont know how to order from Germany (probably quite expensive, when including shipping and taxes)

The idea raised up, to use heatresistors as replacement for the silicon mate.

30 times 100 Ohm resistors (50 W) were skrewed to the aluminum plate into 60 M3 threads drilled into the back of the plate. This should be much more than enough to heat with approx 600 Watt. The resistors were connected 5 in series 6 times in parallel makes (500/6 Ohm = 83 Ohm). P=U²/R=230^2/83 Watt=640 Watt.

HY510 was used as conductive paste, which seems to be a good compromise between quality and price. This conductive paste can be used in a temperature range, which is far outside the usual use-cases for a 3D printer. The 5 series resistors very soldered directly together, the endconnection was done via silconcables and wago-clamps

Before starting the build, I estimated, the temperature fluctuation due to the distance of the load-resistors: Voron_TempFluct

BOM:

- 50W 100 Ohm resistors 75 Stk. ~45,- Eur

- HY510 ~6,- Eur (30g (>10ml), but only 3ml needed)

- M3x6 75 Stk 7,- Eur

- Silicon cable 2m 5,- Eur

- T-fuse (125° 15 A) reused from Voron 5,-

- 3950 thermistor (reused) 5,- Eur

- M3 thread whirling tool 5,- Eur (Used to CNC mill the M3 threads)

- D2 end milling cutter 5,- Eur

- D4 shaft for my CNC motor 9,- Eur

- wago clamp 2 Stk 5 each 2,- Eur

Sum: 94,- Eur

Uncountable amount of coffee and time excluded from this calculation makes it more cheap, than the Fabreeko silicon heater

TODO show foto of my thermo camera for two different temperatures.

TODO show heating curve + stabilisation with calibrated PID (+/- 0.1 deg for 70 and 100° celsius as initial result)

The aluminum block in the middle was foreseen to hold a PT1000 and a second 3950 thermistor

but first measurements have shown, that a 3mm hole in the middle of the back of the aluminum plate serves better and faster for the PID.

Temperature measurement with thermo camera shows convincing results:

The temperature in the back and front are too low. This is probably due to the Ventilator of the Nevermore. Unluckily I do not have a photo, when the original LDO heater was equipped.

temperature and heater curve, when heating up from room temperature to 110°C (230 F) from klippy.log